4-20mA RS485 Dissolved Oxygen Meter (PCDO01) Oxygen Concentration Testing for Industrial Water Application

Nanjing Wotian Technology Co., Ltd.- Display:LED

- Appliance:Water Treatment, Sewage Treatment, Fish Farming...

- Portable:Non Portable

- Certification:RoHS

- Type:Dissolved Oxygen Meter

- Measuring Range:0 - 20mg,L,0 - 200%,0 - 400hpa

Base Info

- Model NO.:PCDO01

- Resolution:0.01mg,L,0.1%,1hpa

- Accuracy:±1.5%Fs

- Repetition:±0.5%Fs

- Temperature Measurement Type:Ntc 10K,PT1000

- Output Type:4 - 20mA, RS485

- Max.Loop Resistance:750Ω

- Communication Protocol:Standard Modbus-RTU (Customizable)

- Power Supply:AC220V, 50Hz,60Hz (Optional 24V)

- Alarm Relay:AC250V, 3A

- Transport Package:Standard Export Packing

- Specification:0.75kg

- Trademark:WTsensor

- Origin:China

- Production Capacity:5000 Pieces,Month

Description

Basic Info.

Model NO. PCDO01 Resolution 0.01mg/L,0.1%,1hpa Accuracy ±1.5%Fs Repetition ±0.5%Fs Temperature Measurement Type Ntc 10K/PT1000 Output Type 4 - 20mA, RS485 Max.Loop Resistance 750Ω Communication Protocol Standard Modbus-RTU (Customizable) Power Supply AC220V, 50Hz/60Hz (Optional 24V) Alarm Relay AC250V, 3A Transport Package Standard Export Packing Specification 0.75kg Trademark WTsensor Origin China Production Capacity 5000 Pieces/MonthProduct Description

PCDO02 Dissolved Oxygen MeterOProduct overview

PCDO02 Optical Dissolved Oxygen Online Analyzer, an intelligent online chemical analyzer, is widely applied for continuous monitoring and measurement of dissolved oxygen, saturation, oxygen partial pressure and temperature in the solution in the industry of thermal power, chemical fertilizer, environmental protection, metallurgy, pharmacy, biochemistry, food and water, etc.

Continuous monitoring measurement data is connected with the recorder via transmitting output to realize remote monitoring and recording. It can also be connected with RS485 portal via MODBUS-RTU protocol to access computer for monitoring and recording.Application Scope

Features

Support dissolved oxygen(DO), saturation(SAT), oxygen partial pressure(OPP) and temperature measure.

Support upper/lower limit control, transmitting output, RS485 communication.

Configurable manual and auto temperature offset function.

Configurable upper/lower limit alarm and delay.

Configurable hummer and LCD backlight switch.

Optional language, Chinese and English.

Zero oxygen and full-scale calibration.

Applications

Sewage treatment

Waste water treatment

Water treatment

Drinking water

Surface water: river, lake and sea

Fishery

Boiler feed water (trace oxygen measurement)

| Measuring principle |

• Sensor design:

- Oxygen-sensitive molecules (markers) are integrated in an optically active layer (fluorescence layer).

- The surface of the fluorescence layer is in contact with the medium.

- The sensor optics are directed at the underside of the fluorescence layer.

• There is an equilibrium between the oxygen partial pressure in the medium and that in the fluorescence layer:

- If the sensor is immersed in the medium, the equilibrium is established very quickly.

• Measuring process:

- The sensor optics send green light pulses to the fluorescence layer.

- The Oxygen-sensitive molecules instantly becomes excited and releases red light.

- The duration and intensity of the response signals is directly dependent on the oxygen contents and the partial pressure.

- If the medium is free from oxygen, the response signals are long and very intense.

- Oxygen molecules quench the Oxygen-sensitive molecules. As a result, the response signals are shorter and less intense.

• Measurement result:

- The sensor returns a signal that is in proportion to the oxygen concentration in the medium.

- The medium temperature and air pressure are already taken into account calculated in the sensor.

- In addition to the standard values of concentration, saturation index and partial pressure,

the sensor also returns a raw measured value in μs. The value corresponds to the decay time of the fluorescence and is approx. 20 μs in air and approx. 60 μs in media free from oxygen.

| Installation method |

1 Dissolved oxygen transmitter

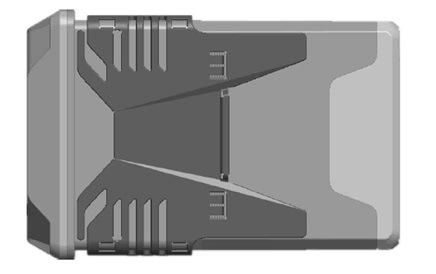

Open a 92.5 * 92.5(mm) installation hole on the instrument cabinet or installation panel (the dimension is 100*100*150mm). Insert the instrument into the installation hole and latch on the butterfly clasp, as shown below.

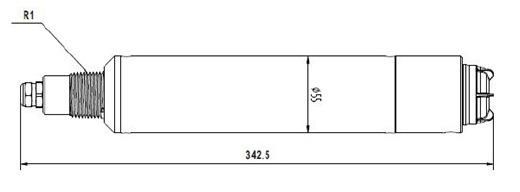

2 Dissolved oxygen sensor

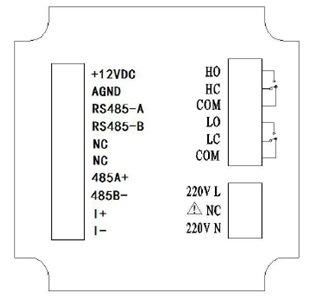

| Identification of terminal |

Wiring diagram

+12VDC: Power supply of dissolved oxygen electrode

AGND: Power negative of dissolved oxygen electrode

RS485-A: Dissolved oxygen electrode communication-A

RS485-B: Dissolved oxygen electrode communication-B

NC: Null

RS485(A+): RS485 communication interface A+

Optical Dissolved Oxygen Online Analyzer - Operation Manual

RS485(B-): RS485 communication interface B-

I(+):4-20mA output port +

I(-): 4-20mA output port -

HO: High alarm of normal open relay

HC: High alarm of normal close relay

COM: Common port

LO: Low alarm of normal open relay

LC: Low alarm of normal close relay

COM: Common port

220V L: AC220V fire wire

NC: Null

220V N: AC220V zero wire

About Us:

Certifications:

FAQ:

1. Q: Are you manufacturer or trading company?

A: We are manufacturer which focuses on pressure sensor for 33 years.

2. Q: What international certificates do you have?

A: ISO9001, CE, RoHS Certificated.

3. Q: What is your production capacity?

A: We produced 1500000 pieces pressure sensor in year 2017.

4. Q: What is the lead time of your product?

A: Stocks are available for some products. The typical lead time is 8~14 working days for product without customization.

Note: lead time may vary base on different products. Please contact us for detailed lead time.

5. Q: What is the warranty of your products?

A: Our warranty time is 18 months after shipment.

6. Q: Do you provide customized products?

A: Yes, we can laser mark your logo, model and product information according to your requirement. We provide OEM and ODM service.