Three-Angle Portable Glossmeter with PC Software Gms Hot

Sino Age Development Technology- Delivery:Within 3 Workdays Upon Receipt of Full Payment

- Color:Gery

- Memory:900 Data or 30 Groups, CF Card (Optional)

- Power Supply:+5V, AA*4

- Dimension (mm):164×58×88

- Net Weight(G):520

Base Info

- Model NO.:GT series

- Key Words:Portable Gloss Meter

- Transport Package:Carton

- Specification:SGS

- Trademark:SADT

- Origin:China

- HS Code:9031809090

- Production Capacity:50 Piece,Pieces , Week

Description

Basic Info.

Model NO. GT series Key Words Portable Gloss Meter Transport Package Carton Specification SGS Trademark SADT Origin China HS Code 9031809090 Production Capacity 50 Piece/Pieces / WeekProduct Description

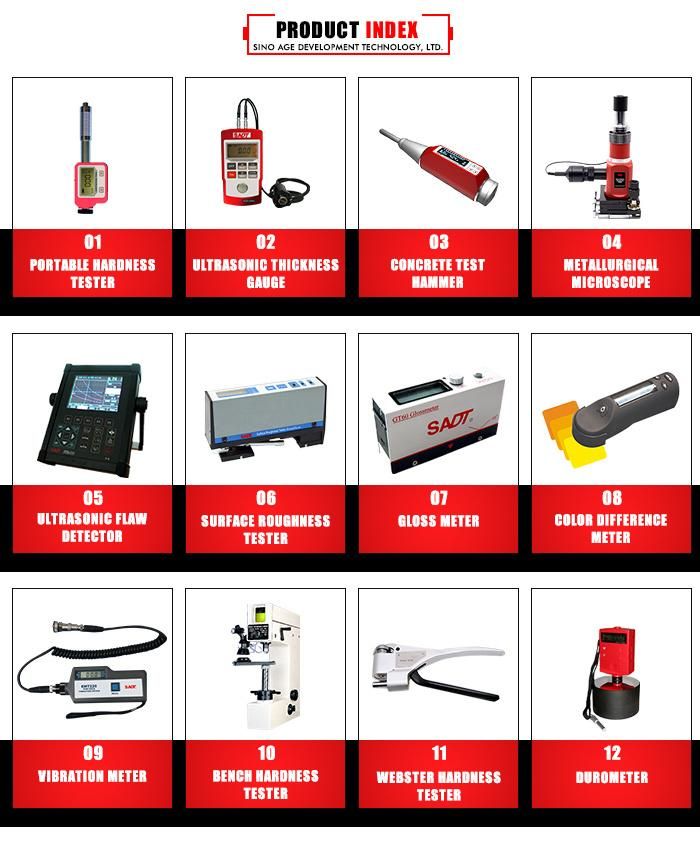

Digital Glossmeter / Vancometer Portable Gloss Meter with PC Software GMSIntroduction

GM Series gloss meters include GMS tri-angle gloss meter and GM60 single angle gloss meter. They are designed and manufactured to test gloss according to internation standards ISO2813, ISO7668, ASTM D523, ASTM D2457 and China standards GB/T9754, GB/T13891, GB/T7706 and GB/ T8807. The technical parameters is up to JJG696-2002. GM Series gloss meters can be widely used to measure painting, coating, plastic, ceramics, leather products, paper, printing, floor materials and so on.

Key features

Precision appearance design, more suitable for human characteristic, easy to use.

Three-angle gloss data is displayed simultaneously, can satisfy various require-ments. (Only for GMS)

Large memory for measurement data.

Latest Bluetooth function and removable memory card to transmit data conveniently.

Speical designed gloss software to analysis data and output.

Prompt for low battery and full memory.

With internal Bluetooth module or USB interface, GM gloss meter can transfer data with PC easily. The measuring data also can be exported to printer via printing interface. Optional SD card makes the memory as large as you want.

Specifications

| Model | GMS | Model | GMS |

| Application | Painting, printing, floor material, plastic,ceramics, leather, hardware, plating | Interface | USB / printer /Bluetooth |

| Measuring Range(Gu) | 0~120, 120~2000 @ 20° 0~120, 120~1000 @ 60° 0~120, 120~160 @ 85° | Software | Data managing software |

| Readout Error(Gu) | ±1.5 (0~120) ±1.5%(120~2000) | Power Supply | +5V, AA*4 |

| Repeatability | ±0.5 (0~120) ±0.5%(120~2000) | Working Environment | 10~40ºC, <85%RH, |

| Aperture (mm) | 20°, 60°, 85° | Dimension (mm) | 164×58×88 |

| Measurement Spot (mm) | 10×10 @ 20° 9×15 @ 60° 5×38 @ 85° | Net Weight(g) | 520 |

| Memory | 900 data or 30 groups, CF card (optional) | Standards | ISO2813, ISO7668, ASTMD 523, ASTM D2457, GB/T9754, GB/T13891, GB/T7706, GB/T8807 |