Oil and Gas Equipment/Laboratory Gas Chromatograph

Chongqing TOP Oil Purifier Co., Ltd.- Appliance:Oil,Liquid,Earth

- Ray Type:.

- Gaspath System:Double

- Detector:Tcd,Double Fid,Ni Reburner

- Energy Resolution:0.5

- Certification:CE, ISO, IEC

Base Info

- Model NO.:GC-7890

- Chromatography Type:Gas Chromatography

- Transport Package:Wooden Case

- Trademark:TOP OIL TESTER

- Origin:Chongqing, China

- HS Code:9027

- Production Capacity:100 Sets,Month

Description

Basic Info.

Model NO. GC-7890 Chromatography Type Gas Chromatography Transport Package Wooden Case Trademark TOP OIL TESTER Origin Chongqing, China HS Code 9027 Production Capacity 100 Sets/MonthProduct Description

Oil and Gas Equipment/Laboratory Gas ChromatographGC-7890 Gas Chromatograph is a universal, multi-purpose, high-performance chromatographic analysis equipment. The instrument is equipped with dual gas-line analysis system, can be configured TCD, FID, ECD, FPD, NPD five detectors; can be operated on constant temperature or 7-step program heating; can be installed packed column or capillary column; can be used for stigma injection or rapid vaporization injection analysis; can be configured thermal analyzer, headspace sampler, automatic liquid sampler and other different injection device,to form different performance instruments to meet different users, different objects, different application place.

The instrument is controlled by computer, operated by keyboard, displayed by Chinese/English switchable LCD screen, with the advantages of high electronic circuit integration, good reliability, simple operation, long-term operation.

The oven is equipped with a rear door automatic cooling system. Each heating zone (the incubator incubator, capillary injector incubator, detector incubator, auxiliary incubator, oven thermostat) is separated from each other by a heat insulating material, so that the heat conduction between the heating zones is minimized and the temperature of each heating zone can be independently controlled.

Injector incubator can accommodate two packed columns and one capillary column at the same time. The gas flow and pressure control system is installed inside the instrument gas-line box. The injection system installed at the top of the instrument requires vertical injection.

The signal output of the instrument can be connected to a peripheral drawing device such as a recorder, an integrator, and a computer.

Temperature control index

Oven temperature:

Room temperature plus 6 ºC ~ 370 ºC; (in increments of 1 ºC),

(set effectively parameter up to 399 ºC, allowing using but not to guarantee the technical index)

Temperature fluctuation: no more than ± 0.1 ºC; (ambient temperature change 10 ºC or power supply voltage change 10%).

Temperature gradient: ± 1% (temperature range 100 ºC ~ 350 ºC).

Program heating step: 7 step.

Heating rate: 0 ~ 40 ºC / min (set in increments of 0.1 ºC).

Cooling rate: not more than 3 min when oven cool from 200 ºC to 100 ºC.

Time setting: 6000 (min).

Detector temperature:

Room temperature plus 20 ºC ~ 350 ºC (index parameters).

(Set parameters: room temperature plus 6 ºC ~ 399 ºC effective, allowing using but not to guarantee the technical index ).

Temperature control accuracy: not more than ± 0.1 ºC.

The remaining heating zone temperature:

Room temperature plus 20 ºC ~ 350 ºC (index parameters).

(Set parameters: up to 399 ºC effective, allowing using but not to guarantee the technical index ).

Temperature control accuracy: not more than ± 0.2

Features

1. Large-screen LCD display; rich and intuitive displaying content; convenient to set parameters.2. Unique microcomputer automatic ignition device.

3. Stable and reliable digital zero setting to avoid baseline instability caused by the zero setting of potentiometer.

4. Have analysis acquisition automatic start function to seriously guarantee the synchronization of analysis and acquisition.

5. Sample injector adopts ration card to guarantee accurate sample injection and good repeatability.

6. Intelligent back pullout automatic cooling system with frequency conversion function; with fast cooling speed; achieve real near room temperature operation.

7. Column adopts unique tracking temperature rising to avoid detector contamination caused by rapid heating of column chamber .

8. With gas stopping/leaking protection and prompts functions; maximize the protection for TCD tungsten and column from damage.

9. Temperature control adopts Multichannel Integration Solid-State Relay to make temperature control stable and reliable.

10. Fault self-diagnosis function. At any time to show failure cause and alarm indication.

11. Adopt microcomputer control, keyboard setting, LCD display, with memory function.

12. High performance detector and methanator. The detection capability completely meet the Electric Power Ministry's determination of gas component content in transformer oil.

13. Adopt one injection, second diffluence column with quick analysis speed and good repeatability.

14. Double hydrogen flame design to make low content hydrocarbons and high content CO, CO2 separately detected to avoid mutual interference.

15. Adopt new type column packing material, double column temperature flow to make the C2H2 detection time quicker, sensitivity higher and analysis period shorter.

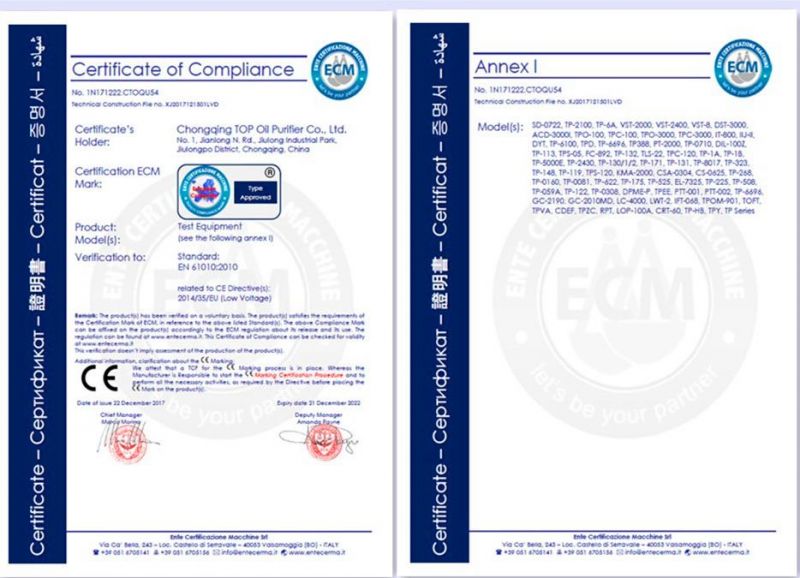

Related Certificates:

Our testers:

Our Company:

Located at Chongqing city--a southwest electromechanical manufacturing center as well as national municipality, Chongqing TOP is a professional leading manufacturer and supplier of oil purifiers and various related testers. We consists of departments respectively for technological development, machinery manufacture, instrument manufacture, quality control etc. On basis of mature development and manufacture technology and highly qualified production management team, the products own high quality, easy operation, excellent performance and lone service life.

TOP Oil Purifiers are widespread in the fields of electric power, petrifaction, mineral, shipbuilding, steel construction, bridge, automobile and railway, playing a great role in reducing energy consumption for clients as well as environmental pollution. We provides you with reliable oil purifiers such as transformer oil purifier, turbine oil purification machine, hydraulic oil purifier, lubricating oil filtration machine, fuel oil restoration, oil and water separator, oil regeneration equipment, waste oil recycling equipment etc.

TOP Testers works on the development, production, market, technical and after-sale service for petrochemical analyzers, transformer substation electrical testing equipment and circuit detecting equipment. Main products are water content testers, surface/interfacial tension testers, flash point testers, kinematic viscosity testers, oil acidity testers, insulation oil dielectric strength testers, transformer characteristics testers, relay protection testers, high voltage testing equipment etc.

Honest Team - TOP always honestly treat you and keep faith to make you satisfied with every cooperation with us.

Sincere Communication - TOP sincerely communicate with you to guarantee the provided products to be your ideal ones.

Reliable Quality -TOP own high quality and high performance for every TOP product is under strict quality control and testing.

Service Commitment - TOP bring you prompt, considerate and professional aftersale service and technical support, and explore technology future together.