Manul Type Cut off Machines for Metallographic Lab Test Use

Jinan Chenji International Trade Co., Ltd.- Sample Type:Solidity

- Processing Method:Cutting

Base Info

- Model NO.:SQ-100

- Warranty:1 Year

- Environment:Normal Pressure and Temperature

- Display:Pointer Display

- Performance:Semi-automatic

- Power Supply:220V

- Certification:CE

- Weight:190kgs

- Customized:Customized

- Working Voltage:380V 50Hz

- Spindle Speed:2800r,Min

- Grinding Wheel Specifications:300×2×32mm

- Motor:Y2-100 L-2 3.0kw

- Dimensions:950×880×1500mm

- Equipment Quality:120kg

- Transport Package:Plywood Box

- Specification:950× 880× 1500mm

- Trademark:OEM ODM

- Origin:China Shandong Others

- HS Code:8460402000

- Production Capacity:2000 Set Per Year

- Package size per unit product:60.00cm * 50.00cm * 80.00cm

- Gross weight per unit product:90.000kg

Description

Basic Info.

Model NO. SQ-100 Warranty 1 Year Environment Normal Pressure and Temperature Display Pointer Display Performance Semi-automatic Power Supply 220V Certification CE Weight 190kgs Customized Customized Working Voltage 380V 50Hz Spindle Speed 2800r/Min Grinding Wheel Specifications 300×2×32mm Motor Y2-100 L-2 3.0kw Dimensions 950×880×1500mm Equipment Quality 120kg Transport Package Plywood Box Specification 950× 880× 1500mm Trademark OEM ODM Origin China Shandong Others HS Code 8460402000 Production Capacity 2000 Set Per YearPackaging & Delivery

Package size per unit product 60.00cm * 50.00cm * 80.00cm Gross weight per unit product 90.000kgProduct Description

Manul Type Cut off machines for Metallographic lab Test Use

Usage of the Cutter

This machine is suitable for cutting samples of various metal and non-metal materials in order to observe the metallographic and petrographic structure of the material. The machine is equipped with a cooling device, and the configured cooling liquid can take away the heat generated during cutting, and avoid the sample from overheating and burning the sample tissue. The machine is easy to use and reliable. It is the equipment for making samples in factories, research institutes and laboratories of universities and colleges.

Technical Data

1. Power supply: three-phase four-wire (380V, 50Hz)

2. Spindle speed: 2800 rpm

3. Grinding wheel specifications: 350×2×32mm

4. Maximum cutting diameter: 100mm

5. Motor: Y2-100 l-2 3.0KW

6. Equipment quality: 120k

| Name | Spec | Unit | Qty | Note |

| Manual sample cutting machine | SQ-100 | Set | 1 | |

| Product Manual | Copy | 1 | ||

| Product certification | Copy | 1 | ||

| Packing List | Copy | 1 | ||

| Wrench | 36 | PCS | 2 | |

| Big throat hoop | φ32-φ44 | PCS | 2 | |

| Small throat hoop | φ16-φ25 | PCS | 2 | |

| Cut slices | 350mm | PC | 1 | |

| Inlet pipe | 2.5m | PC | 1 | |

| Wrench | Hexagon socket m8 | PC | 1 | Optional |

| Long hair brush | PC | 1 | ||

| Aggravate foot | M12 | PCS | 4 | |

| Outlet pipe | 2.5m | PC | 1 | |

| Environmentally Friendly Cooling Lubricant | 2500ml | BOTTLE | 1 | |

| Cooling water tank | 50 liters | PC | 1 | |

| Water pump | 380v | Set | 1 |

Usage

Inner Structure :

SIX STEPS FOR AN INFORMATIVE SAMPLE

The task of metallography i.e. materialography is to ascertain the structure of the material by means of macro & microscopic procedures. Even metals display a crystalline structure- in the same manner as non-metallic crystals such as the quartz rock crystal among others -whose features can be ascertained qualitatively and quantitatively.

In order to be able to examine a material and come to a satisfactory conclusion about its quality, grinding & polishing of a sample is an important initial step in metallography i.e. materialography. This scratch-free step suitable for macro and/or microscopic observation must have a representative, sharp-edged and level surface of the material to be examined, which allows clear recognition of its structure. Therefore it is essential that no scratches, unwanted fractures, foreign bodies or deformations appear in the preparation of the material. Preparation normally takes place in 6 steps: cut-off, mounting, grinding, polishing, etching and microscopic examination. Finally, evaluation of the sample by means of macro or microscopy as well as hardness testing; that is if so required.

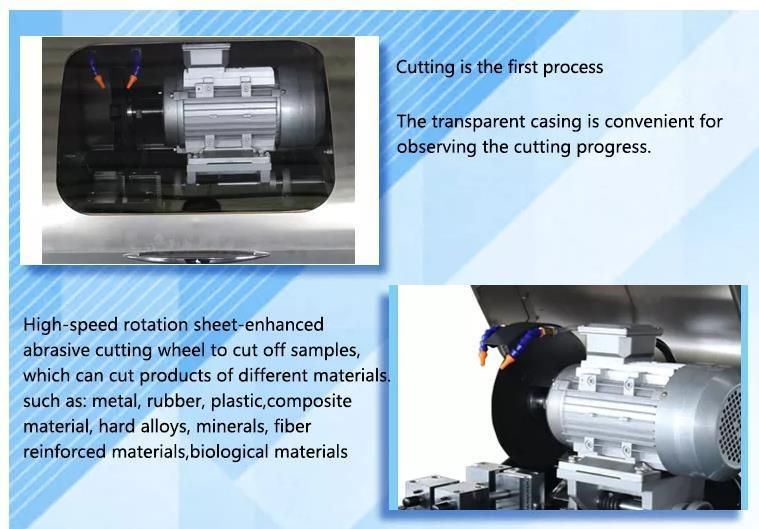

Cut-off

Step number one involves cutting off a section to be tested/examined as a sample of the material by means of a cut-off machine (e.g. a wet abrasive cut-off machine of the series known as "Brillant") and the corresponding clamping tools which have been designed to clamp at strategic positions. If the specimen is large enough, it can be mounted and then ground and/or polished with a holder without further preparation.

Special clamping tools

An almost endless list of materials and geometries have to be securely positioned inside the machine cutting chamber. In addition to the standard assortment, there are special clamping devices for extraordinary problem samples, one example being the pulsed clamping system for CFK, GFK or Titanium cut-offs.

Mounting

Small-sized samples on the other hand, have to be mounted initially to improve handling and/or protection for the edges, which takes place using either cold or hot mounting procedures. In the case of the latter, the samples are mounted in a so-called mounting press- here referred to as the hot mounting press, one of the series known as "Opal". In the course of this process, the sample is surrounded by special plastic granulate (diverse Duro or thermoplastics), which is then pressed together using heat and hydraulic pressure. Using this method means that the material is fully enclosed in plastic and is therefore optimally ready for the next metallographic preparation step.

Grinding and Polishing

In order to make the crystal structure visible, the sample surface must be initially ground even, and then polished.

The grinding & polishing process takes place using a unit with the same name; either per hand, as for example with pre-grinding on the pre-grinding unit ("Jade"), or conversely automatically - which is more normal for today's metallography laboratories. In contrast to manual grinding & polishing, in the case of automatic grinding, the sample is fixed in a sample holder and pressed onto the grinding medium (grinding paper, grinding wheel etc.) with a grinding & polishing head ("Rubin"). The grinding/polishing medium actually sits on top of a working wheel. A series of grinding steps follows whereby each new step makes use of even finer grinding medium, to proceed step-by-step towards the grade of polished surface desired. The sample has to be rotated through 90° after each grinding step, in order to cancel out the grooves left over from contact with the previous grinding medium. During the whole process, a lubricating & cooling fluid ensures that the sample is cooled and waste material washed away. The sample should be cleaned regularly with water and alcohol between the single steps, to ensure that waste material (sludge) and coarse grinding particles from the previous step are not carried over to the following step.

The following polishing phase uses various polishing cloths. The last scratches left over from the previous grinding are polished away by removing a last final layer. This step in metallography is best served with a diamond suspension in poly or mono-crystalline form as final polishing medium. In particular, where many samples are polished one after one another, the use of an automatic grinder & polisher (such as in the case of Systemlabor or even the Systemautomat) is of advantage.

Etching

After completion of the last polishing step, first predictions about the purity of the material can be ascertained through the different reflexions. In order to make the crystal structure visible for being contrasted, the sample has to undergo a further preparation step either manually per immersion into an etching liquid or through deployment of an electrolytic etching unit such as the model "Kristall". The particular etching fluid for the particular sample has the effect of changing the reflexion behaviour of the integral crystalline component so that an optical difference is possible. Following etching, the sample is washed in alcohol and then rapidly & thoroughly dried under a flow of warm air.

Using the Microscope and evaluation

If the crystalline structure contrasts correctly in this manner, then the sample can be evaluated. Through making use of observation under the macro or microscope as well as evaluation per modern picture analysis & image archiving programs, a string of statements about such as state of heat treatment, welded seams, crystalline structure and the quality of materials can be made. Furthermore, quite often metallography allows conclusions to be drawn from the manufacturing process and/or causes of failure in cases of damage.

If and when a hardness test is to be performed (micro & universal hardness tester) then all common-place test procedures such as according to Vickers, Brinell, Rockwell or Knoop are brought into use.