En 367 and ISO 9151 Protective Clothing Heat Transfer Test Equipment

Chongqing Advanced Technology Co., Ltd.- After-sales Service:Response in 12 Hours

- Warranty:12 Months

- Test Standard:En 367 and ISO 9151

- Power Supply:220V, 10A

- Weight:30kg

- Dimension:470*600*600mm3

Base Info

- Model NO.:HTI

- Gas Supplies:Compressed Air and Propane

- Test Temperature:25±5ºC

- Function:Determination of Heat Transmission

- Height of Crucible:80 Kw,M2

- Power Consumption:200W

- Applicating:Protective Clothing Testing

- Transport Package:Plywood Case

- Specification:Stainless steel

- Trademark:AI

- Origin:China

- HS Code:9031809090

- Production Capacity:10 Sets,Month

Description

Basic Info.

Model NO. HTI Gas Supplies Compressed Air and Propane Test Temperature 25±5ºC Function Determination of Heat Transmission Height of Crucible 80 Kw/M2 Power Consumption 200W Applicating Protective Clothing Testing Transport Package Plywood Case Specification Stainless steel Trademark AI Origin China HS Code 9031809090 Production Capacity 10 Sets/MonthProduct Description

Introduction

A new term heat transfer index (HTI) has been introduced to avoid confusion with the thermal protective index (TPI) or other terms used in previous versions of this test. HTI calculated from the mean time in seconds to achieve a temperature rise of 24±0.2ºC when testing by this method using a copper disc and a starting temperature of 25±5ºC. The heat transfer index provides a method of grading materials which does not imply that the material tested will give any precise protective time under actual use conditions.

Features

1.The Heat Transmission Test Apparatus is designed and manufactured according to EN 367 and ISO9151 standards.

2.The apparatus consists of the burner, the cover sheet and the specimen holder with copper calorimeter.

3.The cover sheet and the specimen holder are controlled via pneumatic transmission which is automatically controlled by software.

4.A horizontally oriented test specimen subjected to an incident heat flux of 80KW/m2 from the flame of a Meker burner beneath it.

5.The heat passing through the specimen is measured by means of a small copper calorimeter on top of and contact with the specimen.

6.The time to record a temperature rise of 12 or 24ºC in the calorimeter is recorded in seconds.

7.The calorimeter cooling device shorten the test time.

8.The mean result for the three test specimens is calculated as the HTI.

9.The calibration of heat flow density of 80 kW/m2 is performed automatically by software of Heat Transmission Test Apparatus.

Introduction of main machined parts

| No. | Name | Craft |

| 1 | Cover sheet | Customized corundum plate |

| 2 | Control cabinet | Customized by reputable cabinet factory |

| 3 | Other auxiliary facilities | Aluminum processing |

| 4 | Burner | USA Meker |

| 5 | Auxiliary fixtures | Aluminum processing or stainless steeel |

Main Components of HTI Heat Transmission Test Apparatus

| No, | Name | Remark |

| 1 | Operation method | Automatic controlled by computer |

| 2 | Software | Designed by AIC |

| 3 | Acquisition card | Taiwan ADVANTECH |

| 4 | Computer | Dell or Lenovo desktop |

| 5 | Copper plate heat flow meter | Customized |

| 6 | Button | ABB |

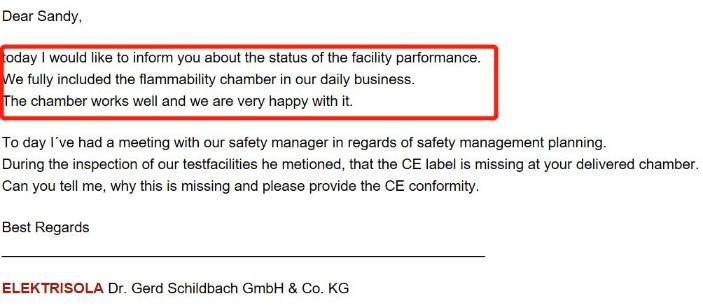

Customer Feedback

Germany

USA

Transporation

FAQ

1.What's the delivery time?

About 40 days .

2.What's your payment terms?

30% paid by T/T in advance,70% paid by by T/T before shipping.

3.What's your guarantee terms?

The warranty of all products is 1 year.During this period,we are responsible for all faults caused by us.And we can supply life-long technical support.

4.Can you supply training?

We can supply training in our factory and online training for free.If onsite installation and training are required,please pay for tickets,accommodation and salary USD150/Day for every person.