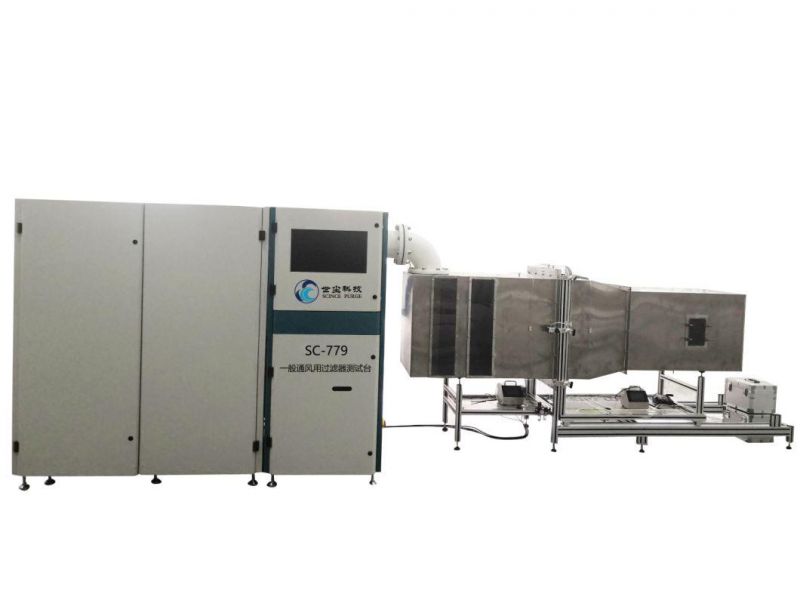

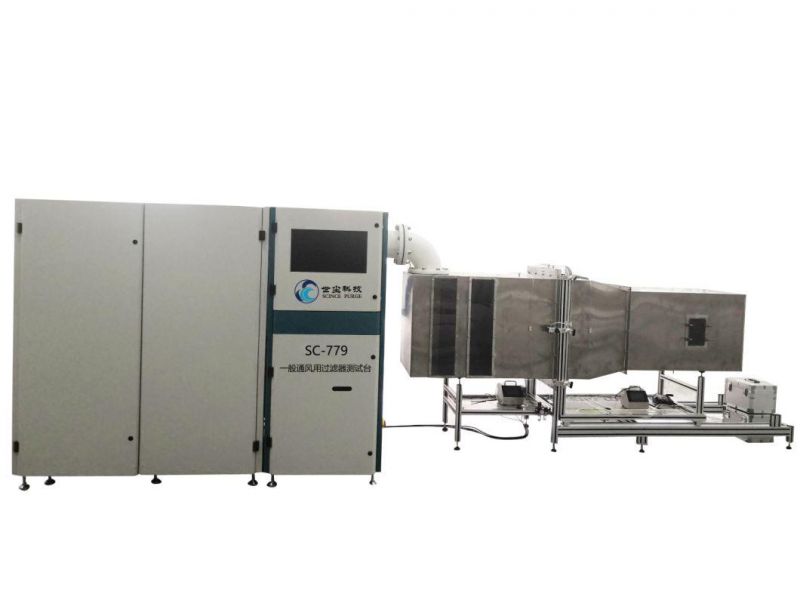

General Ventilation Filter Air Purification System for Flow Rate-Resistance Curve Testing

Scince Purge Technology (Qingdao) Co., Ltd.- Output Air Volume:150~1500m3,H

- Aerosol:Dehs or Kcl

- Resistance Range:0~500PA

- Demension:5400*1400*1800mm

- Transport Package:Wooden Package

- Specification:5400*1400*1800mm

Base Info

- Model NO.:SC-779-1901

- Trademark:Scince

- Origin:Suzhou, China

- Production Capacity:50sets,Year

Description

Technical Data SheetItem Parameter Output air volume 150-1500m3 / h Maximum size of the filter can be tested 745*610*120mm Aerosol DEHS or KCl Laser particle counter zero count ≤10pc/min (0.2~0.3μm) Sampling flow rate ≥2.83L/min, ±5% Resistance range 0~500Pa Resistance accuracy 0~70Pa, ±2Pa; >70Pa, ±3% Dimension 5400mm×1400mm×1800mm

Product Pictures

Features

1. It is convenient to install the filter into the fixture. Test aerosol and clean air are evenly mixed and passed through the tested filter. Resistance and filter efficiency are obtained by detecting the pressure difference and concentration difference downstream and upstream of the filter. Filters are graded according to their average efficiency.

2. The electrical control and measurement system of the test system uses the upper computer software system and the Siemens PLC to form an electrical control cabinet, ensure the stability of the control system.

3. The test system adopts an advanced online monitoring software system. It has two modes.

Automatic mode: installed the filter, input the filter size , set the test flow, and test process (including self-cleaning, particle number judgment etc.) completed automatically. Test results are directly reflected on the computer LCD display. If air volume under different resistances is needed,

Manual mode: It is used to test the flow rate - resistance curve.

4. Start and stop of the aerosol generator, the conversion of the upstream and downstream laser particle counter, and inflation and sealing all are automatically controlled by the corresponding solenoid valves.

5. The test system uses positive pressure, sets the air volume through software, and uses the frequency converter to realize automatic control of air volume.

6. Functions such as test report printing, label printing, and database management are available.

7. The system uses a bypass diluter with large dilution ratio and reliability.

Product Pictures

Features

1. It is convenient to install the filter into the fixture. Test aerosol and clean air are evenly mixed and passed through the tested filter. Resistance and filter efficiency are obtained by detecting the pressure difference and concentration difference downstream and upstream of the filter. Filters are graded according to their average efficiency.

2. The electrical control and measurement system of the test system uses the upper computer software system and the Siemens PLC to form an electrical control cabinet, ensure the stability of the control system.

3. The test system adopts an advanced online monitoring software system. It has two modes.

Automatic mode: installed the filter, input the filter size , set the test flow, and test process (including self-cleaning, particle number judgment etc.) completed automatically. Test results are directly reflected on the computer LCD display. If air volume under different resistances is needed,

Manual mode: It is used to test the flow rate - resistance curve.

4. Start and stop of the aerosol generator, the conversion of the upstream and downstream laser particle counter, and inflation and sealing all are automatically controlled by the corresponding solenoid valves.

5. The test system uses positive pressure, sets the air volume through software, and uses the frequency converter to realize automatic control of air volume.

6. Functions such as test report printing, label printing, and database management are available.

7. The system uses a bypass diluter with large dilution ratio and reliability.