Customized 4 Channel SF6 Gas Leakage Detecting System GDWG

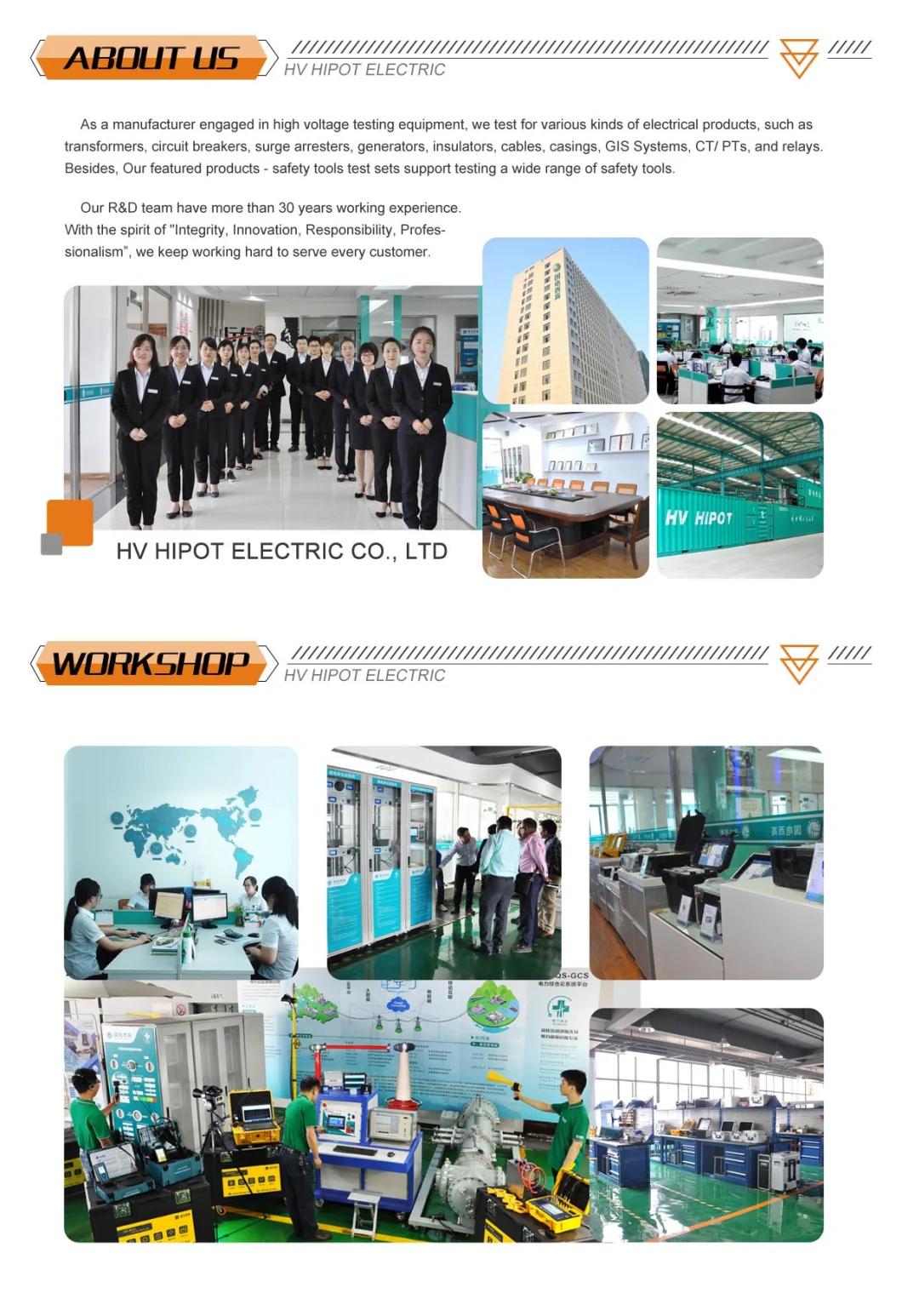

HV Hipot Electric Co., Ltd.- Brand:HV Hipot

- Customized:Customized

- Portable:Portable

- Gas:SF6

- Type:Electrochemical Gas Analyzer

- Measuring principle:Non-dispersive infrared sensor (NDIR)

Base Info

- Model NO.:GDWG

- Measuring range:double path 0-2000ppmv (resolution 0.1) 0-50ppmv (

- Resolution:0.1ppmv and 0.01ppmv

- Accuracy:2%FS

- Transport Package:Standard Export Wooden Box

- Specification:560*510*340mm

- Trademark:HV Hipot

- Origin:Wuhan, China

- HS Code:9030899090

- Production Capacity:5000set,Year

Description

Basic Info.

Model NO. GDWG Measuring range double path 0-2000ppmv (resolution 0.1) 0-50ppmv ( Resolution 0.1ppmv and 0.01ppmv Accuracy 2%FS Transport Package Standard Export Wooden Box Specification 560*510*340mm Trademark HV Hipot Origin Wuhan, China HS Code 9030899090 Production Capacity 5000set/YearProduct Description

Customized 4 Channel SF6 Gas Leakage Detecting System GDWGI. General information

GDWG SF6 Gas Leak Detecting and Measuring Systems high precision and sensitivity detecting system, which use NDIR technology principle and pumping cycle principle. It is used to detect few SF6 gas in the pipe quantitatively and qualitatively. Based on the design principle of infrared (detecting SF6 gas wavelength 10.2-10.6μm), the SF6 detection will be accurate.

Application

SF6 detection and analysis of pipe type

SF6 detection and analysis of storage container

Benefits

- No radiation.

- No need to replace high pressure high pure argon gas regularly.

- No need to approach high pressure gas.

- No need to replace sensors regularly, cost-effective.

- Stable performance, low maintenance cost. No need to make linear calibration every year.

- No affect by moisture and environment pollution.

- Detection sensitivity is up to 0.1ppmv and 0.05ppmv.

- When serious leakage or the SF6 gas concentration is up to 100%, it will not be polluted or damaged.

- 3.5inch OLED display.

- One screen display SF6 gas concentration, temperature and humidity, battery indication, time and pump status.

- Friendly human machine interface.

- Fast measurement speed, up to10s to achieve stable data.

- Only response for SF6 gas, not for other gas.

- Make sure that no sensor poisoning occurs at any concentration.

- Small size, easy to carry, suitable for on-site working.

- Super-light aluminum with full shielding shell.

- Diaphragm pump suction sampling mode to ensure the tightness of the test gas path.

III. Specifications

| Measuring principle | Non-dispersive infrared sensor (NDIR) |

| Measuring range | double path 0-2000ppmv (resolution 0.1) 0-50ppmv (resolution 0.01) limit range 0-100% |

| Resolution | 0.1ppmv and 0.01ppmv |

| Accuracy | ±2%FS |

| Repeatability error | ≤±1% |

| Response time | ≤10s |

| Recovery time | ≤15s |

| Long time stability(span) | ≤±20ppm, more than 1000 hours |

| Long time stability(zero) | ≤±20ppm, more than 1000 hours |

| Zero shift | ≤±1%(F.S/year) |

| Linear error | ≤±1% |

| Storage temperature | -20 ~ +60ºC |

| Operation temperature | -20 ~ +50ºC |

| Working humidity | 0-95% (no condensation) |

| Sampling mode | Diaphragm pump, flow up to 1L/min. |

| Working voltage | 220VAC±10%, 50Hz or Battery F750/8.4V. |

| Air pressure | 800-1150hPa |