En ISO 9239-1, ASTM E648 Radiant Flooring Panel Apparatus

Chongqing Gold Mechanical & Electrical Equipment Co., Ltd.- Application:Flammability Analyzer for Flooring Materials

- Item Name:Flammability Analyzer for Flooring Materials

- Standard:ISO 9239-1; ISO 9239-2; ASTM E648; ASTM E970

- Utilities:Bottled Propane Gas, Air Compressor

- K-Type Thermocouples:Range, Ambient About 1500 Degree Centigrade

- Sample Holder:Stainless Steel

Base Info

- Model NO.:GD-ISO9239

- Dummy Calibration Panel Holder:for Measuring Heat Fluxmeter

- Pyrometer:for Measuring Radiant Panel Temperature

- Exhaust:30~85 M3,Min

- Instructions:Provide

- Weight:About 300kg

- Power:AC 220V, 50,60Hz, 20A

- Console Size:600mm(W)* 750mm(D)* 1600mm(H)

- Sliding Platform:for Loading The Specimen

- Warranty:12 Months

- Transport Package:Standard Wooden Case

- Trademark:GOLD

- Origin:Chongqing China(Mainland)

- HS Code:9031809090

- Production Capacity:500 Sets, Year

Description

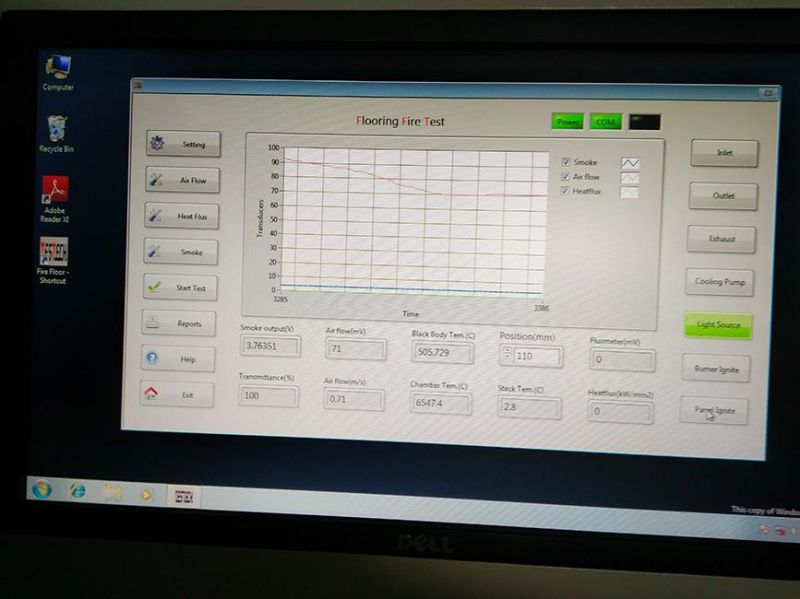

Product Pictures:

Main Features:

1. All structural components are made of stainless steel, beautiful appearance and corrosion resistance.

2. The test chamber is made of the panel (calcium + silicate ) as 13±1 mm of thickness and 650 kg/m3 of nominal density.

3. Air pass dimension between the test chamber and test specimen holder is produced by (0.23±0.03) m3 at both beside of specimen fairly.

4. The calorimeter is imported from the United States, range 50kW/m2.

5. The radiant chamber had a stop of 30±1degree per horizon panel and can be resisted up to 900-degree centigrade. It also should be included in the safety-blocking function.

6. The radiation source is a porous ceramic heat radiating plate of 300mm*450mm and tilted 30 °.

7. The pilot burner should be stationed equally as 0.7mm diameter and 19/EA produced a slop of 60 degrees per centre line bottom.

8. Air velocity of exhaust stack should be attached an exhauster as 2.5±0.2 m/s.

9. It should be used a radiation pyrometer which can be monitor 250mm diameter from about 1.4 meters and has ±5 degree centigrade sod ml accessory with 480ºC to 530ºC (black body temperature) range for adjustment the surface quality of heat of radiant panel.

10. It can be measured hat flow within tolerance from radiant heat panel to 110mm to 910mm at 100mm intervals.

Specification: